Thermoelectric Cooler Cooling Peltier Heatsink Plate TEC1 12V 90W

Thermoelectric Cooler Cooling Peltier Heatsink Plate TEC1 12V 90W

Availability: In Stock

Stock Ready: Kuala Lumpur

Description :

Thermoelectric coolers (TEC or Peltier) create a temperature differential on each side. One side gets hot and the other side gets cool. Therefore, they can be used to either warm something up or cool something down, depending on which side you use. You can also take advantage of a temperature differential to generate electricity.

This Peltier works very well as long as you remove the heat from the hot side. After turning on the device, the hot side will heat quickly, the cold side will cool quickly. If you do not remove the heat from the hot side (with a heat sink or other device), the Peltier will quickly reach stasis and do nothing. We recommend using an old computer CPU heatsink or other block of metal to pull heat from the hot side.

Specifications :

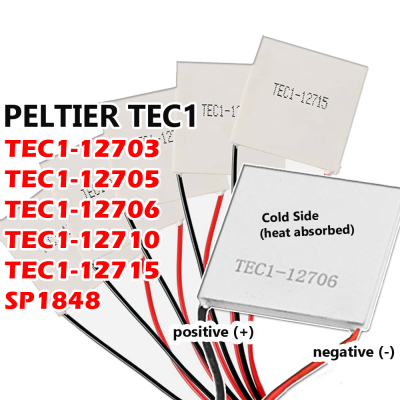

- Model number (optional) : TEC1-12703/TEC1-12705/TEC1-12706/TEC1-12710 / TEC1-12715 / SP1848

- Voltage : 12V

- Umax (V) : 15.4V

- Imax (A) : 6A

- QMax (W) : 92W

- Max heat : 68 Celcuis

- Internal resistance: 1.98 Ohm +/- 10%

- Dimensions : 40mm x 40mm x 3.6mm

- Power Cord : 350mm

- HS Code: 854150

- Type: Cooling Cells

- Usage: Refrigerator/Warmer

Important Note: Heat side requires heat sink all the time. “ Do not run this device with a power supply more than a few seconds without a heatsink mounted to the device! ”

Operating Tips :

- Max. Operating Temperature: 138 Degree C

- Do not exceed Imax or Vmax when operating module.

- Please carry out moisture protection options (seeling) in final application use.

- Life expectancy: 200,000 hours

- Failure rate based on long time testings: 0.2%.

Graph :

Installation :

1. The hot surface Th of the TEC must be attached to a suitable FAN SINK (60x60x40+mm) that is capable of carrying away both the heat pumped by the TEC plus Joule heat from the electric power supplied to the TEC. A heat sink rise of 15C above ambient is typical for many TEC applications. Otherwise, a bigger heat sink must be used to reduce temperature.

2. Care should be taken when applying pressure during installation. Uniform pressure is desired across the mounting surfaces. If uneven pressure is applied, thermal performance may be reduced or damage may occur to the TEC.

3. Clean surface thoroughly, making sure there are no chips, dirt or any foreign substances that may affect bonding. Coat the contacting sides, Th and Tc, with thermally conductive grease or glue.

Performance Specifications

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: